Washing and sorting

Complete line for the receiving of the tomatoes in water with mud disposal system, scraped bottom type, and leaves removal system, roller type

Complete line for the receiving of the tomatoes in water with mud disposal system, scraped bottom type, and leaves removal system, roller type

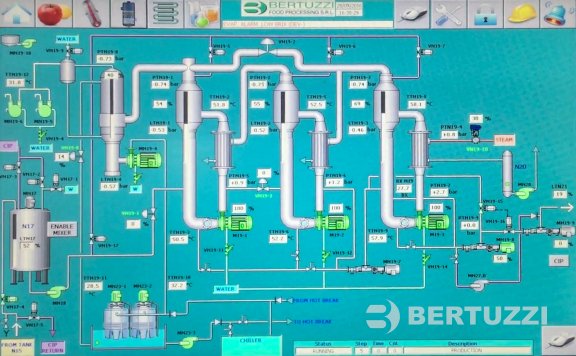

After a quick pre-heating in our hot and cold break system, the chopped tomato is fed to pulper Turbomax, which assures very soft refining.

For the concentration of tomato juice into tomato paste, Bertuzzi developed Frumaco Tomatech, a forced circulation evaporator available, depending on the capacity of the plant, with up to 5 effect.

The tomato paste can be sterilizied by a dedicated tube in tube sterilizer model STTH.

Once sterilized the product can be filled in aseptic bag in drums or in box thanks to Bertuzzi Aseptic Fillers.

From the Tomato paste a wide range of product can be produced. Bertuzzi developed dedicated production lines for the production of Ketchup and vegetable sauces. All bertuzzi lines are fully customized to match the customer recipes and the mostr stringent international requirements

All Bertuzzi lines are designed according to the international food grade requirements and to be fully cleanable by exploiting integrated cleaning procedures and systems or centralized and fully automatic CIP system. The Bertuzzi CipMatic is specifically designed to guarantee a perfect and efficent CIP of the fruit processing plants.